Building a Service Cavity, Stairs, & Mechanicals

Figuring out the Cavity Space

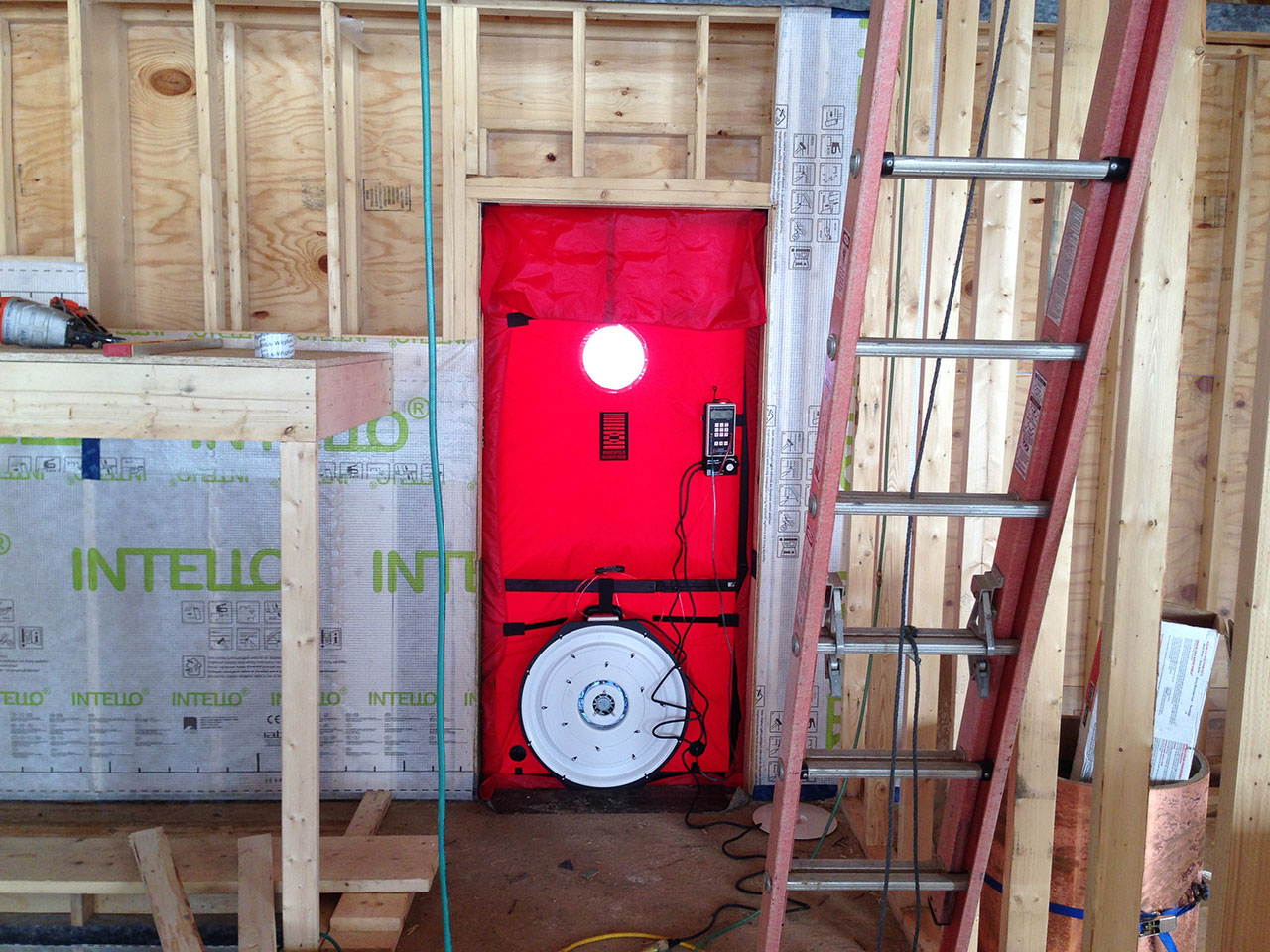

Since we opted for a double air barrier in our design, we preferred not to run any utilities in the space that was to be dense packed with cellulose. This meant we needed somewhere for all the electric wiring to go on our exterior walls. We chose to use an 1-1/2″ service cavity on all exterior walls that required electric outlets.

The one exception to this was the need to run a vent stack behind the kitchen sink. There was no interior partition to run this vent stack, and it was also much wider than the service cavity depth. This will be later dense packed with cellulose, and included in the model by Chris West.

Stairs

The stairs were built at a local facility, made with VT Red Oak, to match the future floors of the home. They are split level with a step at the landing to accommodate the 9′ ceilings of the first floor.

Calculating Heat Requirements

Based on our calculations, we would need about 15,000 BTU/hr for a cloudy day @ 15 degrees F. That meant we could heat the house with a very small heating system. Talking with our plumber, we over-sized our system and went with a Mitzubishi multi head Mini-Split system rated at 48,000 BTU/hr. We installed 4 different heads: 18 kBtu on first, 12 kBtu on second floor, a 9 kBtu in the basement and a 9 kBtu head in the first floor master. This was primarily for the comfort of multi-zones. Additionally, this was a cold climate unit, that may lose efficiency at temperatures below -13 deg F, so we have a nice safety factor when temps get that low.

Each of the 4 heat pump heads has a condensate line, that gravity feeds to a single outlet in the basement.

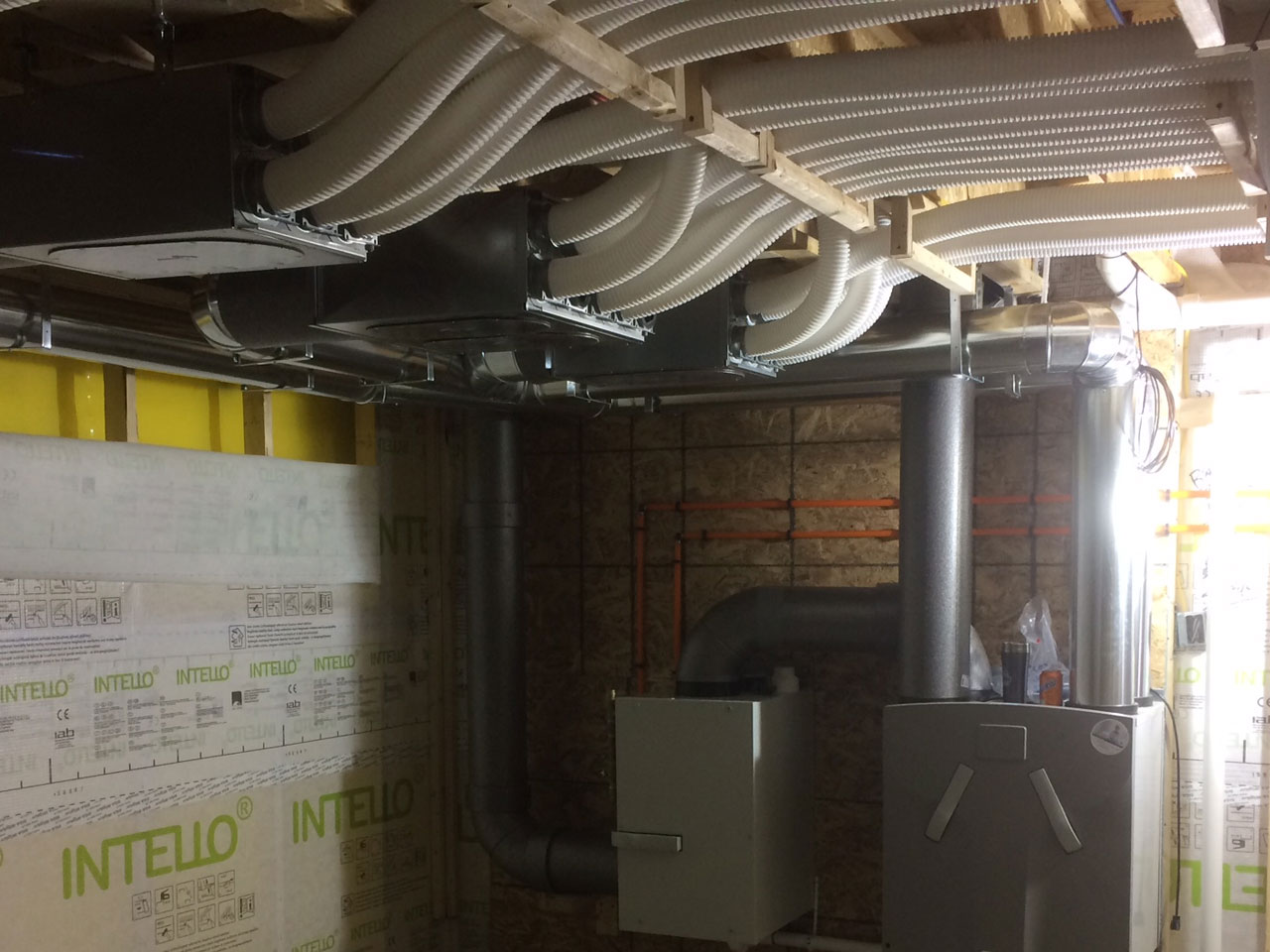

We went with a Zehnder ComfoAir 550 HRV for this home. The unit is shown below, along with its associated equipment. Basically, its a heat exchanger and a lot of 3″ internally smooth tubing. In addition, we purchased the Comfo-Fond to preheat the incoming air with our ground loop. The entire system was balanced at 144 CFM. That means the unit is exhausting 144 CFM to the outside while bringing 144 CFM of fresh air from outside.

Plumbing

Running 30 home-runs (15 supply and 15 return) of 3″ tubing was not an easy feat. Each tube supplies or returns 12 CFM each. Thankfully, our plumber was up to the task and made graceful work of the job. Padding out a couple walls was necessary to allow for all the runs from the second floor through the first floor.

When the plumber was done, we have a very organized ventilation system, complete with ground loop preheat-er, main ex-changer, and 4 distribution boxes. Also shown are the room diffusers (wall and ceiling outlets for the HRV ports).